BRDST PROFILE

BALAI REKAYASA DISAIN DAN SISTEM TEKNOLOGI

(ENGINEERING CENTER – BPPT)

AGENCY FOR THE ASSESSMENT AND APPLICATION OF TECHNOLOGY

BACKGROUND

BALAI REKAYASA DISAIN DAN SISTEM TEKNOLOGI - BPPT, is a unit in Deputy Technology of Information, Energy and Material (TIEM) - BPPT or popularly known as ENGINEERING CENTER – BPPT which carries out tasks in assessment and development of Engineering Design Technology for process industry as well as power plant.

Established in January 1993 with a name as Tim Pusat Pengembangan Rekayasa dan Rancang Bangun BPIS (P2R2B – BPIS) or also known as Engineering Center – BPIS under cooperation of Biro Teknologi Rekayasa Rancang Bangun BPIS with Direktorat TKKE-TIEML-BPPT. In mid 1995 the group changed its name to Pusat Rekayasa Rancang Bangun–BPPT (PRRB) with an initial activity in engineering design of Nuclear Power Plant AP600 for Westinghouse Electric Corporation, USA in the scope of turbine building, which has been a continuous cooperation up to now.

Taking into account the development and improvement of Engineering Center BPPT’s capabilities in engineering design, the team’s facilities, since 4 April 2001 this team was therefore changed to become a technical unit called : Balai Rekayasa Disain dan Sistem Teknologi – BPPT.

VISION

Technology is used to accelerate the economic growth in the frame of social welfare.

MISSION

To make BPPT as a technology center of excellence,

To make BPPT as a society development agency in the field of technology,

To increase the role of technology audit and commercialization,

To increase the competitive ability and the industrial productivity.

OBJECTIVE

To do the government task in the field of the assessment and application of technology according to the valid government regulation.

ENGINEERING SERVICES

The group provides a wide range of engineering services from conceptual design through to fabrication, construction, operation, maintenance and decommissioning, including :

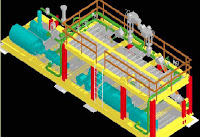

Process System Design, Mechanical Equipment Design, Steel Structure Design, Piping Layout, Piping Stress Analysis, Electrical System Design, Instrumentation And Control System Design, System Modularization, Plant Data & Project Management, 2D/3D Computer Aided Design/Graphics Modeling, Technical Training In Piping and Plant Design, Engineering-Procurement-Construction of Biodiesel Plant.

Engineering Center-BPPT is supported with sophisticated software packages to enable the engineers to integrate all design tasks efficiently from preliminary design task up to generating the final engineering drawings for fabrication and construction. An up to date data management system permits valuable design data to be managed systematically hence ensuring design data accuracy during the project life.

SOFTWARE FACILITIES UTILITY

• Intergraph PDS, a sophisticated Plant Design software package : PFD, P&ID, Wire Work, CRD, CB/CLD, EQP, Piping, Drawing & Isometric Manager, Instrumentation Data Management, etc.

• XSteel, Frame Work Plus for steel structure 3D model design and steel detailing

• Gate Cycle for process design, thermodynamics, heat and mass balance calculation

• Advanced Pressure Vessel (APV)

• PS+CAE Pipe and CAESAR-II for piping stress analysis calculation

• STAAD Pro, for steel and concrete structure stress analysis

• Microstation and Autocad, both are for 2D drafting and 3D modeling

• Microsoft Office utility software: Word, Excel, PP, Access, Project, etc.

• Solaris, Sun Micro-system Server/ Client Operating System

• Clix Intergraph Server/ Client Operating System

• Oracle, Oracle Database Server (RDBMS).

HUMAN RESOURCES / ENGINEER

• Process – 5

• Mechanical – 7

• Electrical – 3

• Instrumentation & Control – 2

• Civil – 2

• Informatics – 2

• Chemical Analyst – 2

• Drafter – 5

• Support Engineer – 10

• Drafter – 5

• Administrator – 5

PROJECT EXPERIENCE

The Group involved in various projects with local as well as overseas clients such as:

• Westinghouse AP600 and AP1000 Nuclear Passive Reactor, Westinghouse Electric Corporation, Pittsburgh, PA. USA

• Madura “BD” Development Project, PT PAL Indonesia

• Bontang LNG Plant Expansion Project -Train H, PT. IKPT ( Inti Karya Persada Teknik )

• Plant Design Training, PT. Rekayasa Industri

• Hg and CO2 Removal in Natural Gas Processes, Piping and Plant Design Training, PT. Pakarya Industri

• TUNU Development Project, PT PALAMEC

• VITA-A Retrofit – Well Platform, PT PALAMEC

• Module Structure Design for AFT Transom Platform for Additional Cable Release System at Widuri Tanker, PT PALAMEC

• Tangguh LNG Plant FEED participation, Bechtel Corp. Houston, USA

• PIM-2 Ammonia and Urea Structure Detailing, PT Rekayasa Industri

• PIM-2 Ammonia and Urea Plant Modeling, PT. Krakatau Engineering Corp.

• Detail design for Mini CPO Plant

• EPC of Biodiesel Plant with capacities of 1 – 3 and 6 – 10 tons/day

Apart from the clients mentioned above, the Engineering Center-BPPT has also interfaced with subcontractors such as Bechtel Corp., Southern Electric Co., Burns & Roe, Ansaldo, Initec and SNERDY (Shanghai Nuclear Engineering Research and Development Institute). And the Group has been acknowledged of being satisfactorily performed the work awarded by Westinghouse Electric Corp.

Fast, reliable and best quality services are our commitment to customers.

Balai Rekayasa Disain dan Sistem Teknologi (BRDST)

(Engineering Center) - BPPT Building 1/ 6th Floor

Jl. MH. Thamrin 8 Jakarta 10340 Indonesia

Telp : 62-21-3915536, 3168240 Fax : 62-21-3915535

BRDST – BPPT, Building 480

Kawasan PUSPIPTEK Serpong, Tangerang

Telp : 62-21-7563217, 68377441 Fax : 62-21-7563273

BALAI REKAYASA DISAIN DAN SISTEM TEKNOLOGI

(ENGINEERING CENTER – BPPT)

AGENCY FOR THE ASSESSMENT AND APPLICATION OF TECHNOLOGY

BACKGROUND

BALAI REKAYASA DISAIN DAN SISTEM TEKNOLOGI - BPPT, is a unit in Deputy Technology of Information, Energy and Material (TIEM) - BPPT or popularly known as ENGINEERING CENTER – BPPT which carries out tasks in assessment and development of Engineering Design Technology for process industry as well as power plant.

Established in January 1993 with a name as Tim Pusat Pengembangan Rekayasa dan Rancang Bangun BPIS (P2R2B – BPIS) or also known as Engineering Center – BPIS under cooperation of Biro Teknologi Rekayasa Rancang Bangun BPIS with Direktorat TKKE-TIEML-BPPT. In mid 1995 the group changed its name to Pusat Rekayasa Rancang Bangun–BPPT (PRRB) with an initial activity in engineering design of Nuclear Power Plant AP600 for Westinghouse Electric Corporation, USA in the scope of turbine building, which has been a continuous cooperation up to now.

Taking into account the development and improvement of Engineering Center BPPT’s capabilities in engineering design, the team’s facilities, since 4 April 2001 this team was therefore changed to become a technical unit called : Balai Rekayasa Disain dan Sistem Teknologi – BPPT.

VISION

Technology is used to accelerate the economic growth in the frame of social welfare.

MISSION

To make BPPT as a technology center of excellence,

To make BPPT as a society development agency in the field of technology,

To increase the role of technology audit and commercialization,

To increase the competitive ability and the industrial productivity.

OBJECTIVE

To do the government task in the field of the assessment and application of technology according to the valid government regulation.

ENGINEERING SERVICES

The group provides a wide range of engineering services from conceptual design through to fabrication, construction, operation, maintenance and decommissioning, including :

Process System Design, Mechanical Equipment Design, Steel Structure Design, Piping Layout, Piping Stress Analysis, Electrical System Design, Instrumentation And Control System Design, System Modularization, Plant Data & Project Management, 2D/3D Computer Aided Design/Graphics Modeling, Technical Training In Piping and Plant Design, Engineering-Procurement-Construction of Biodiesel Plant.

Engineering Center-BPPT is supported with sophisticated software packages to enable the engineers to integrate all design tasks efficiently from preliminary design task up to generating the final engineering drawings for fabrication and construction. An up to date data management system permits valuable design data to be managed systematically hence ensuring design data accuracy during the project life.

SOFTWARE FACILITIES UTILITY

• Intergraph PDS, a sophisticated Plant Design software package : PFD, P&ID, Wire Work, CRD, CB/CLD, EQP, Piping, Drawing & Isometric Manager, Instrumentation Data Management, etc.

• XSteel, Frame Work Plus for steel structure 3D model design and steel detailing

• Gate Cycle for process design, thermodynamics, heat and mass balance calculation

• Advanced Pressure Vessel (APV)

• PS+CAE Pipe and CAESAR-II for piping stress analysis calculation

• STAAD Pro, for steel and concrete structure stress analysis

• Microstation and Autocad, both are for 2D drafting and 3D modeling

• Microsoft Office utility software: Word, Excel, PP, Access, Project, etc.

• Solaris, Sun Micro-system Server/ Client Operating System

• Clix Intergraph Server/ Client Operating System

• Oracle, Oracle Database Server (RDBMS).

HUMAN RESOURCES / ENGINEER

• Process – 5

• Mechanical – 7

• Electrical – 3

• Instrumentation & Control – 2

• Civil – 2

• Informatics – 2

• Chemical Analyst – 2

• Drafter – 5

• Support Engineer – 10

• Drafter – 5

• Administrator – 5

PROJECT EXPERIENCE

The Group involved in various projects with local as well as overseas clients such as:

• Westinghouse AP600 and AP1000 Nuclear Passive Reactor, Westinghouse Electric Corporation, Pittsburgh, PA. USA

• Madura “BD” Development Project, PT PAL Indonesia

• Bontang LNG Plant Expansion Project -Train H, PT. IKPT ( Inti Karya Persada Teknik )

• Plant Design Training, PT. Rekayasa Industri

• Hg and CO2 Removal in Natural Gas Processes, Piping and Plant Design Training, PT. Pakarya Industri

• TUNU Development Project, PT PALAMEC

• VITA-A Retrofit – Well Platform, PT PALAMEC

• Module Structure Design for AFT Transom Platform for Additional Cable Release System at Widuri Tanker, PT PALAMEC

• Tangguh LNG Plant FEED participation, Bechtel Corp. Houston, USA

• PIM-2 Ammonia and Urea Structure Detailing, PT Rekayasa Industri

• PIM-2 Ammonia and Urea Plant Modeling, PT. Krakatau Engineering Corp.

• Detail design for Mini CPO Plant

• EPC of Biodiesel Plant with capacities of 1 – 3 and 6 – 10 tons/day

Apart from the clients mentioned above, the Engineering Center-BPPT has also interfaced with subcontractors such as Bechtel Corp., Southern Electric Co., Burns & Roe, Ansaldo, Initec and SNERDY (Shanghai Nuclear Engineering Research and Development Institute). And the Group has been acknowledged of being satisfactorily performed the work awarded by Westinghouse Electric Corp.

Fast, reliable and best quality services are our commitment to customers.

Balai Rekayasa Disain dan Sistem Teknologi (BRDST)

(Engineering Center) - BPPT Building 1/ 6th Floor

Jl. MH. Thamrin 8 Jakarta 10340 Indonesia

Telp : 62-21-3915536, 3168240 Fax : 62-21-3915535

BRDST – BPPT, Building 480

Kawasan PUSPIPTEK Serpong, Tangerang

Telp : 62-21-7563217, 68377441 Fax : 62-21-7563273

Tidak ada komentar:

Posting Komentar